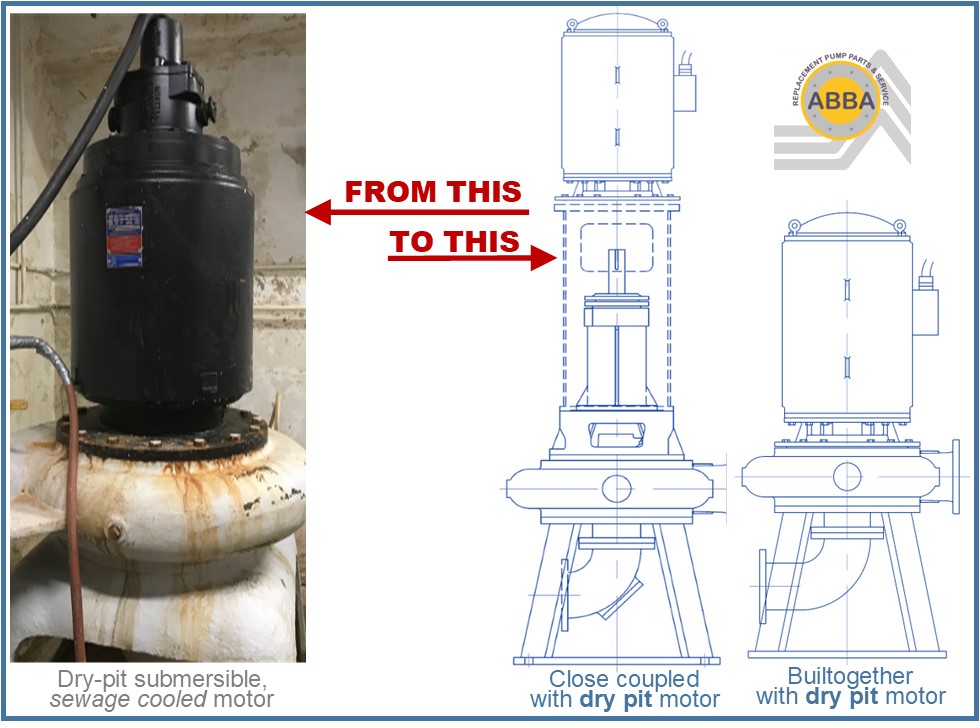

If you’re tired of problematic sewage cooled dry-pit submersible motors AND have no real concern…

Repair or Retrofit? Advantages and Disadvantages of Different Types of Centrifugal Pumps in Wastewater Treatment

Pumps play a major role in water and wastewater treatment plants and pumping stations. Ease of maintenance and repair are important consideration for those responsible for keeping pumps in good working condition. Pumps in pumping stations get waste from its source to the treatment plant and from there pumps are used to move influent, raw water, primary sludge, secondary sludge and return activated sludge through to final effluent.

Centrifugal pumps are among the most commonly used in wastewater treatment plants and pumping stations. At one time, the dry-pit solids handling (or non-clog) pump with flexible drive shaft and motor above grade was quite possibly the most popular style of pump at the WWTP and PS. Today municipalities weigh the benefits of staying with dry pit pumps vs. dry-pit submersibles and true (wet pit) submersible pumps. There are varying opinions about which is better as each offers its own benefits and drawbacks. So between them which is the most convenient to maintain and repair and offer the most trouble free long term operation?

- Dry-Pit Pumps

Dry-pit pump stations are still quite common and found in operation across North America. Typically built below ground, pumps (usually vertical) with flexible drive shafts and above grade air cooled motors are installed in a dry well, adjacent to a wet well. There is usually a superstructure to allow personnel access to the dry well which also houses electrical and other equipment required to run the station. Over the past 100 years, these types of heavy duty centrifugal pumps have proven to be the rugged, reliable, work-horses of the industry.

Advantages and Disadvantages: The primary advantage of dry-pit pumps is that they are not submerged into the wastewater. Because they are not submerged, maintenance personnel can see, touch, listen to and easily repair the pumps. This makes them easier to repair, reduces the amount of time required to diagnose and correct a pump failure. There are fewer health and safety risks associated with repairing dry-pit pumps as well, since they are not submerged, they’re not covered in sewage. Dry wells themselves often provide space required to manoeuver and provide protection from the elements. A disadvantage of a dry-pit pump is it’s typically below ground level and almost always susceptible to flooding.

- Dry-Pit Submersible Pumps

Dry-pit submersible stations a.k.a. submersible dry well stations are growing in acceptance and popularity for dry-pit applications. A dry-pit submersible pump station is not entirely different from a dry-pit station in that it still has a dry and wet well, however the pump configuration, particularly the motor is different. In this configuration, the motor is mounted directly to the pump, eliminating the intermediate shaft. The motor itself will circulate either sewage or glycol (superior to sewage) to cool the motor, which is designed to run continuously in air as well as submerged.

Advantages and Disadvantages: The big benefit of a dry-pit submersible pump is full protection against station flooding. The close coupled motor eliminates problems associated with flexible drive shaft breakages. Many conventional dry-pit pumps can be easily retrofitted to dry-pit submersible quickly and cost effectively. Some disadvantages of the dry-pit submersible can be related to motor failures in sewage cooled style motors. Particles from the sewage settle out and if not properly flushed/cleaned can lead to overheating of the motor. Glycol cooled CLC motors are far superior and virtually maintenance free. Another downside to retrofitting an old dry-pit pump installation with a new dry-pit submersible pump is piping doesn’t always match up which can ultimately be inconvenient and expensive to change.

- Submersible Pumps

As implied, submersible pumps are designed to be submerged directly into the wet well and do not require a dry well. Most commonly these pumps use a pull-up design and run up and down on guide rails. The pump discharge is equipped with a self locking coupling, connecting it to a stationary elbow at the bottom of the pit. Submersible pumps have motors that are designed to run completely immersed in wastewater. Submersible pump stations do not typically have a structure to house a control center, rather a cabinet on the surface above the pit.

Advantages and Disadvantages: The advantage of submersible pump stations is they are less expensive to construct as they have only a wet pit and may not have any above ground construction. The disadvantage of submersible pumps is they are not readily accessible. Maintenance personnel cannot easily monitor the running condition of a submersible pump as while submerged one cannot see, listen to our touch the pump. Essentially, the pump must fail before any problems with it can be detected. Since they are submerged, they must be uninstalled to be inspected and repaired. There are also health and safety risks as they will be covered in sewage. A crane is required to uninstall the pump and since there is no structure on the surface, the pump must be transported to a local repair facility for inspection and repair. This can make submersible pumps more expensive to repair and may take longer as compared to the dry-pit and dry-pit submersible pumps described above.

How ABBA Can Help

Call today to learn more about how ABBA can help convert conventional dry-pit pumps to dry-pit submersibles. It’s convenient and cost effective – no piping changes!

ABBA Pump Parts and Service is a qualified and experienced Aftermarket Parts Solutions Specialist (APSS). For 30 years, ABBA has specialized in manufacturing high quality replacement centrifugal pump parts & assemblies for municipal wastewater and water authorities. Our experience has evolved from a strong background in pump design, manufacturing, application engineering and pump repair.

We have sold hundreds of retrofit pumps to municipalities across North America and our business remains strong and growing. We pride ourselves on quality and service knowing that we must always be at least equal to or better than our O.E.M. competitors in every respect.

ABBA manufactures replacement parts, rotating assemblies and complete pumps to fit or replace existing Fairbanks Morse (Pentair), Allis Chalmers (FLYGT A-C), Worthington, Smith & Loveless and many more. Replacement centrifugal pump parts, assemblies and pumps are our specialty.

We guarantee our pumps and parts are equal to or better than the O.E.M. for ‘Fit, Form and Function’ and have done so for 30 years with very few warranty claims and zero performance related issues. All of our designs, standards and specifications are based upon original O.E.M. designs, standards and specifications with improvements or enhancements where possible. All of our products are guaranteed to be direct drop in replacements.

More information on converting dry-pit pumps to dry-pit submersibles – click

1-800-268-5142