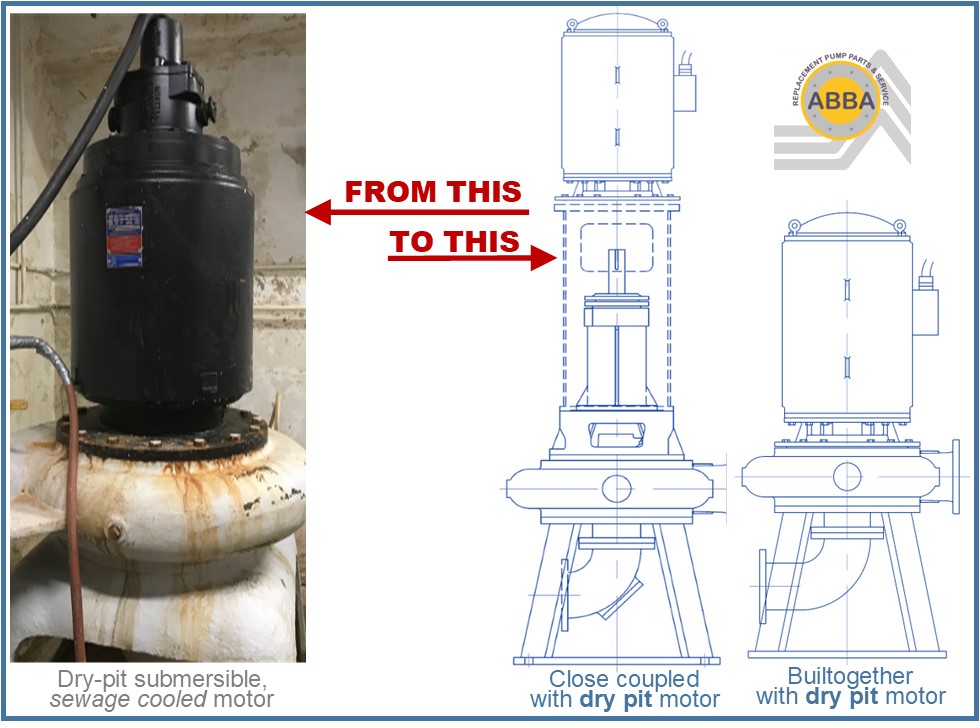

If you’re tired of problematic sewage cooled dry-pit submersible motors AND have no real concern…

Fresh bums, clogging problems and single vane impellers.

Can single vane impellers solve pump clogging problems for municipalities?

Flushable wipes, flushable toilet cleaning sponges, cardboard applicators and even plush, multi-ply toilet paper are wreaking havoc on sewage pumps and causing serious problems for municipal maintenance personnel. Manufacturers of these products maintain they are compatible with municipal sewage pumps. Arguably there is a difference between something that will flush and something that will break down before it reaches the wastewater treatment plant pumps. But, in both the U.S. and Canada, wastewater authorities argue that guidelines are not stringent enough. While regulators work to keep the “flushable” label off any products that do not pass a third-party test, how are clogging problems solved at sewage pump stations?

It’s not a sexy subject but short of spending millions to install powerful grinders and screens which may not always solve the problem, can single vane impeller retrofits eliminate pump clogging problems?

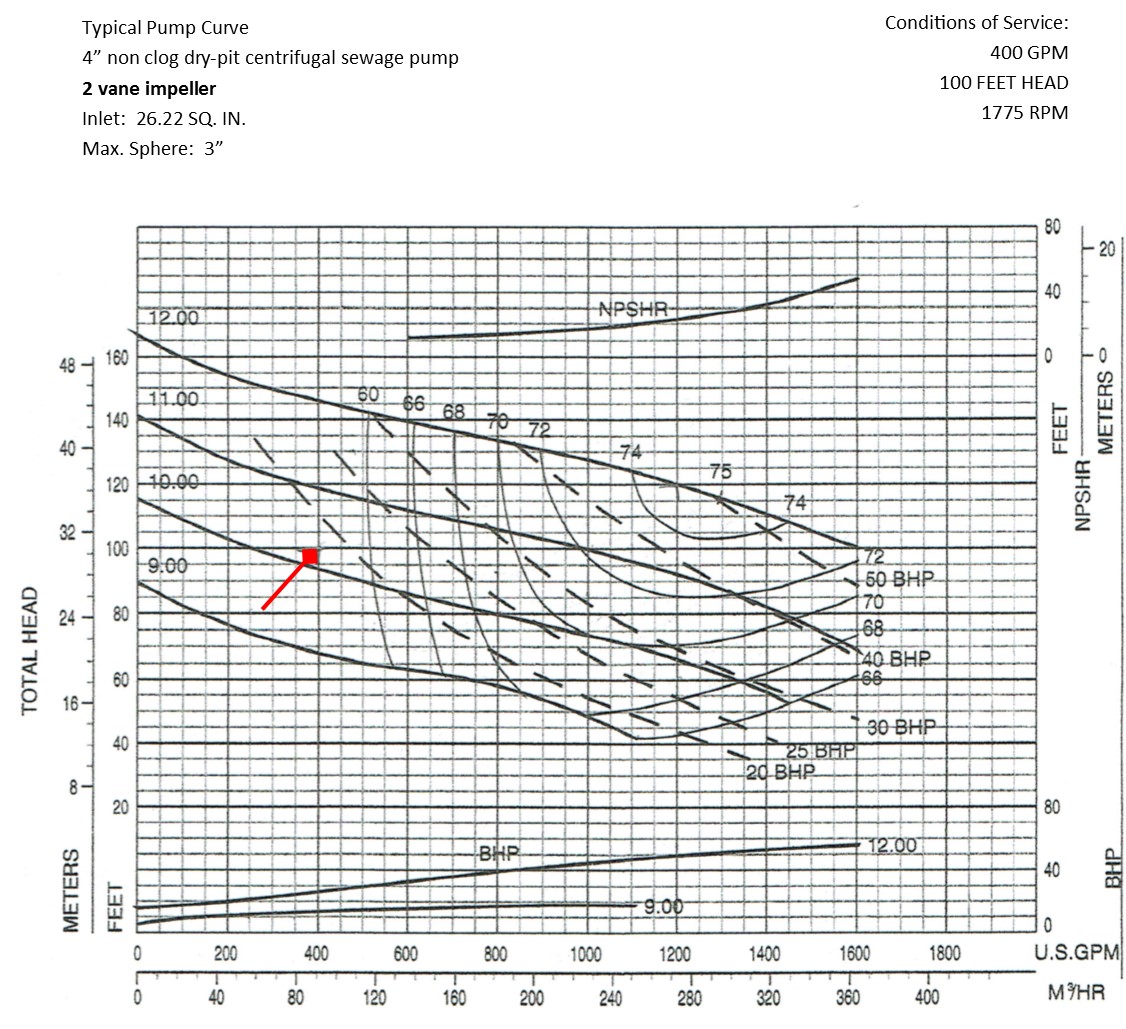

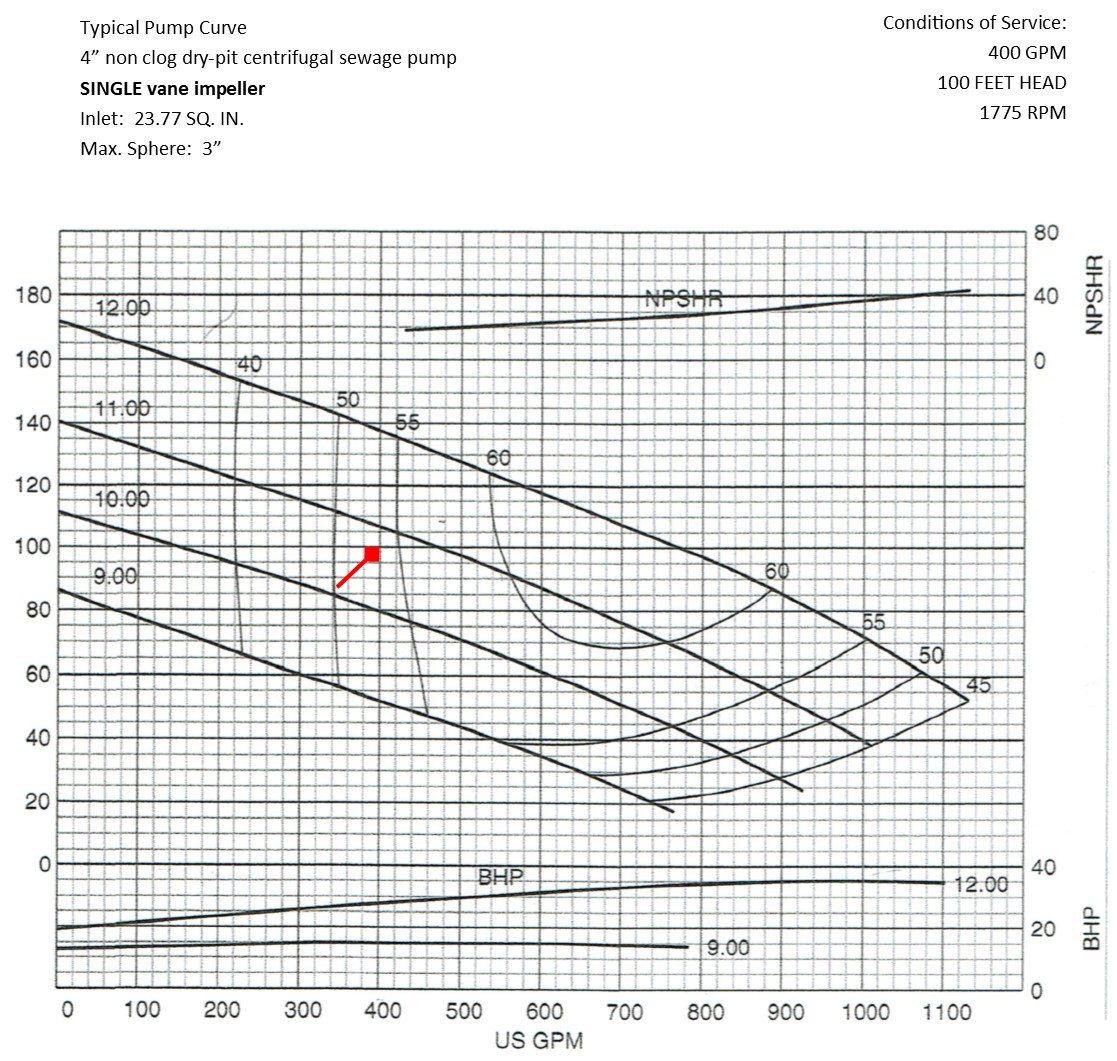

With standard 2 vane impellers, sewage comes up into the eye of the impeller and is pulled in the direction of both passageways at the same time. If there is any hesitation as to which way sewage and material goes, it continues to spin in the eye of the impeller until more material enters the eye, does the same thing and eventually balls up and becomes a magnet for more rags and stringy material.

A single vane impeller also called mono vane or bladeless, has only one passageway and direction for sewage and stringy materials to go. The possibility of rags collecting and clogging is greatly reduced. In fact the single vane impeller is 10 – 25 times less likely to clog, compared to the standard 2 vane impeller. Many small pump stations operate at relatively low flows and well to the left of best efficiency point. In most of these cases a single vane impeller will provide the same flow and head but operate close to the best efficiency point, often with higher efficiency. When used by municipalities with sewage flows that are relatively low and in sewage pumps up to 6” discharge size the single vane impeller can offer “night and day” performance and reliability compared to its 2 vane counterpart. But before retrofitting pumps with this optional impeller, one must consider desired conditions of service and must carefully look at “peak period demand” to make sure the single vane impeller will meet peak flow requirements.

But what if the OEM doesn’t make a single vane retrofit? Fortunately ABBA Parts makes a single vane retrofit that can be installed in many different brands, sizes and models of dry pit or submersible centrifugal sewage pumps. It’s true the single vane impeller is not perfect for every situation but ABBA Parts has hundreds of satisfied customers who love not having to open up their pumps daily to clean out the blockages. Call ABBA Parts today to see what we can do to solve your clogging problems with a custom single vane impeller retrofit.